Silkscreen Printing

What is Silkscreen Printing ?

- Silkscreen printing methods are the oldest forms of printmaking.

- This technology found its way to the west in the 15th century. The original material used in screen printing was silk. Hence the name silkscreen printing. Today polyester is the fabric of choice.

- It is a stencilling method that involves printing ink through stencils block that are supported by a porous fabric mesh stretched across a frame called a screen.

- Silkscreen printing is ideally suited for bold and graphic designs.

How is it done ?

- A multi-coloured design must be separated into 4 individual standard colour & print it on a negative films as we want to apply each ink colour separately. Each negative film will be used for a separate stencil block.

- The printed negative films are to be placing on top of a special coated screen of the stencil block . The coating is light sensitive and will etch a photo-negative of the design on the screen of the stencil block.

- The basic printing process is the forcing of ink through a stencil block onto material with a squeegee. This is called “pulling”. Each colour must be printed in the same place and in the same order for each print to resemble the original.

- Printing Inks is ultraviolet (UV) base & to be categorise as four standard in primary pigments which called C.M.Y.K (Cyan, Magenta, Yellow & Black). In certain design it require the fifth pigment to get the special solid colours but however that is depend on the customer requirement and of course the additional cost will be incurred.

- Each ink will need to dry before we can apply the next colour.

Weakness & Strength

- The affordability of silkscreen printing occurs when the size of the order increases as the fixed cost is then spread over the volume of items to be printed.

- As an order size increases, the costs for silkscreen printing falls, because the initial setup costs of the silk-screening are spread over a larger number of print product. At some point, silkscreen printing will actually become more economical than Inkjet / digital print and that are also incredible durable which should last for months especially for outdoor !

- The major drawback of silkscreen printing is that it is a multi-stage process and the initial set up costs are expensive.

- The final print result can not compare with the high resolution print format such as inkjet or digital printing.

WHAT WE OFFER

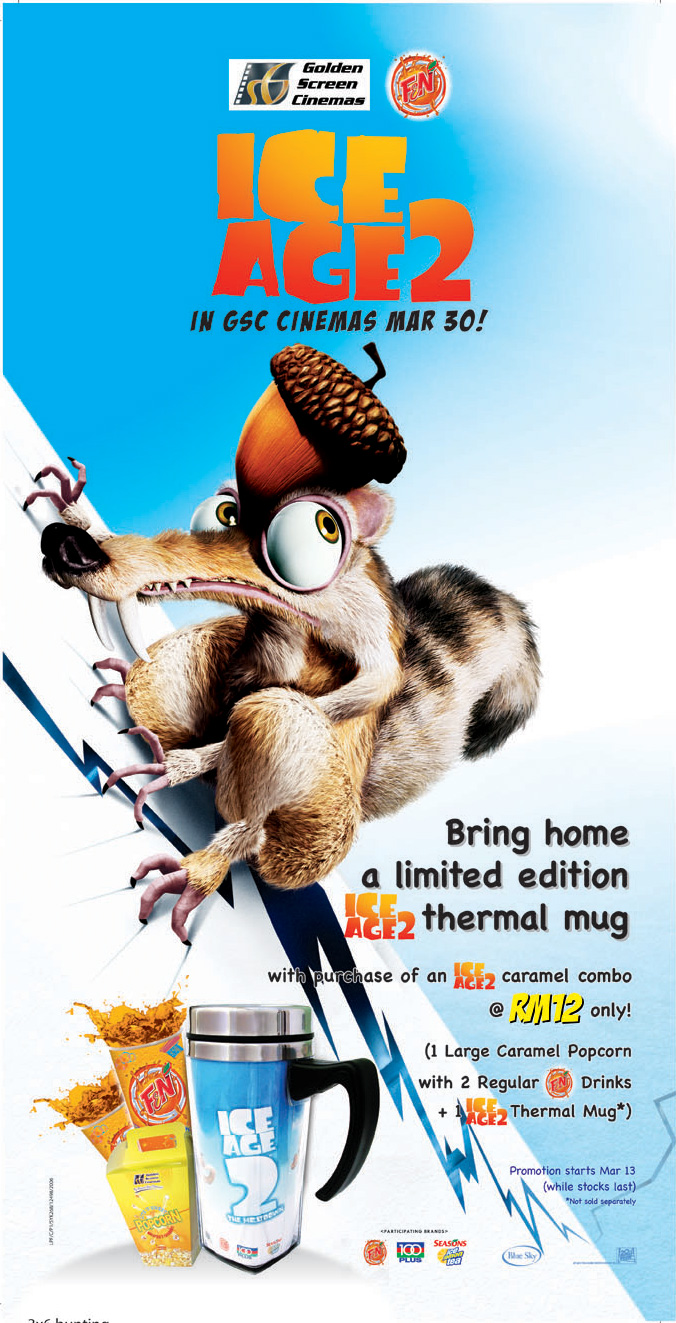

We accept any order of buntings or stickers ranges from 50pcs to 50,000pcs or more, from 1 color up to 4 color buntings with various material options, for an affordable price.

Production output @ 7,500*pcs per day

Choice of finishing :

a) PVC pipe with string on top & bottom

b) Wood on top & bottom

Available Material :

a) Covek

b) Synthetic Paper 180micro

c) PVC White Sticker